What Exactly Is CAN Bus and How Does It Carry Vehicle Data?

Before decoding engine speed, vehicle distance, or diagnostic messages, we must understand the wiring, structure, and behavior of the network carrying this data.

This is where CAN Bus becomes essential.

What Is CAN Bus?

CAN Bus, short for Controller Area Network, is a two-wire communication system used inside nearly every modern heavy vehicle. It allows electronic control units (ECUs) such as the engine controller, brake controller, transmission module, and dashboard to exchange information instantly and reliably.

The simplest way to imagine it is as a shared data highway where every ECU sends small updates continuously.CAN was created to reduce complex wiring, improve reliability, and support the increasing number of electronic systems inside vehicles.

Two Wires That Carry the Entire Vehicle’s Data

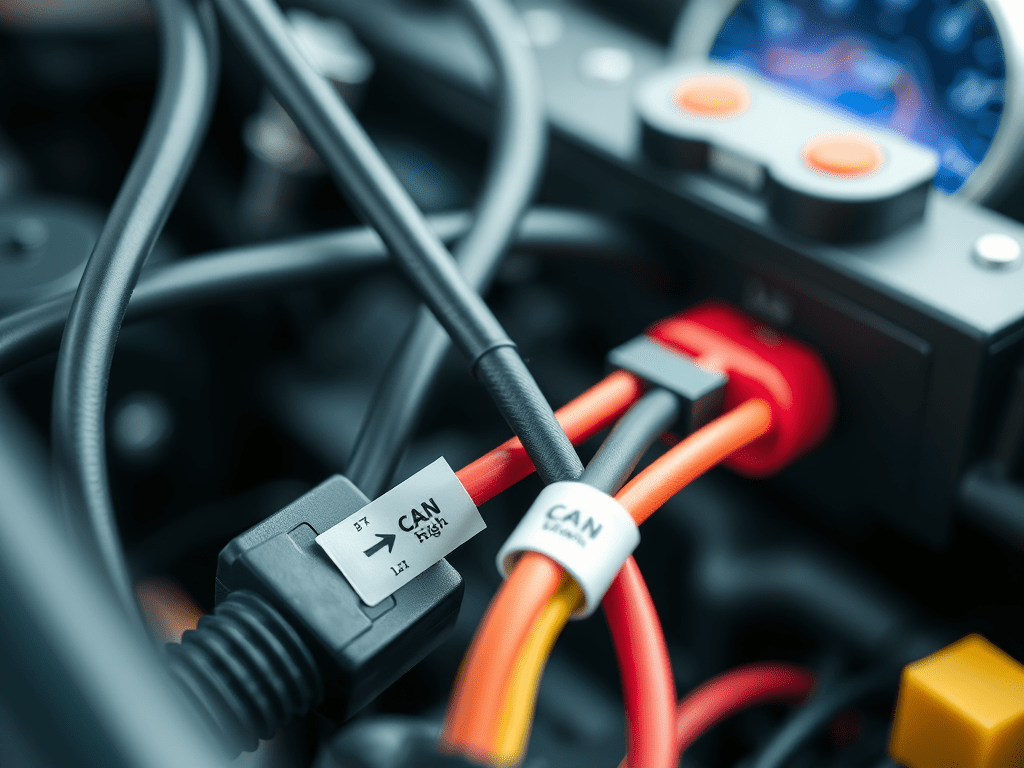

Despite handling hundreds of messages per second, the CAN network uses only two wires:

- CAN High

- CAN Low

Both wires are twisted together to reduce electrical noise, especially important in diesel engines, alternators, and high-current environments. These two wires carry all engine, speed, diagnostic, and sensor updates that an ELD needs to read.

Multi-Master, Priority-Based Messaging

One of the strengths of CAN is that any ECU can transmit data at any time. There is no central controller. Instead, each system communicates as needed.If two ECUs transmit simultaneously, the message with higher priority takes control of the bus, and the other automatically waits without causing errors. For example, a safety-related message like brake pressure will always take priority over non-critical data like fuel economy statistics.This structure keeps the vehicle’s communication fast and predictable.

Why CAN Bus Is Extremely Reliable

From our work at HardFault developing ELD hardware and firmware, CAN is one of the most dependable data sources inside a vehicle. It was designed specifically for harsh, noisy, and high-vibration environments.

Reasons for its reliability include:

- Built-in error detection

- Automatic re-transmission of corrupted messages

- Acknowledgment bits to confirm delivery

- No single point of failure due to shared wiring

- Real-time performance with very low latency

This reliability is essential for ELDs, where speed data, engine hours, and ignition status must be accurate and consistent.

How CAN Bus Connects to ELD Devices

Every modern truck exposes its CAN Bus through a diagnostic connector, commonly a 9-pin port or OBD-style connector. This is where an ELD plugs in.

Once connected, the ELD listens passively to the CAN messages the vehicle is already broadcasting. These include:

- Vehicle speed

- Engine speed (RPM)

- Engine hours

- Odometer information

- Fault codes

- Throttle position

HardFault’s ELD firmware is designed to carefully filter and interpret these messages without interfering with the vehicle’s network.

CAN Bus: The Foundation of Vehicle Communication

Understanding CAN Bus is the first step towards understanding how any heavy vehicle communicates. In summary:

- CAN provides the physical channel for data

- ECUs continuously share information over CAN

- J1939 defines the structure and meaning of this information

- ELDs listen to CAN to extract required engine and driving data

Without CAN Bus, modern vehicles would not be able to coordinate their functions safely, and ELDs would not have access to the information required for compliance.

Conclusion

CAN Bus may appear simple from the outside, but it is one of the most sophisticated and reliable communication systems ever built for automotive use. It enables quick, accurate, and defect-free communication between all vehicle systems. For HardFault’s ELD solutions, this dependable data backbone ensures accurate logs, reliable insights, and consistent performance across different vehicle brands.

Leave a comment